|

Zhaoqing Yili Garment Machinery Co., Ltd

|

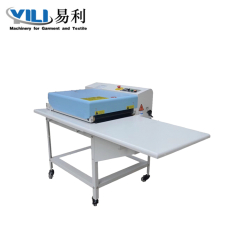

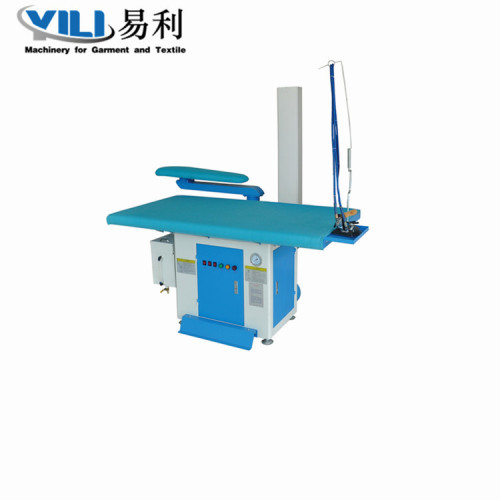

Steam Vacuum Ironing Table Inbuilt with Steam Boiler

| Price: | 950.0 USD |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Applicable Industries:Garment/Textile Factory

Video outgoing-inspection:Provided

Machinery Test Report:Provided

Marketing Type:Ordinary Product

steam vacuum ironing table inbuilt with steam boiler

| Technical specification | |||||||

| Model | YL-128A-D-U | ||||||

| Voltage&Frequency | AC 220V/380V 50HZ | ||||||

| Furnace heating pipe power | 5kw (for one steam iron) | ||||||

| Water pump power | 1.1kw | ||||||

| Vacuum motor power | 800w / 750w | ||||||

| Total power | 6.9kw / 6.85kw | ||||||

| Water tank capacity | 16L | ||||||

| Steam pressure | 0.4Mpa | ||||||

| Rated steam consumption | 7kg/h | ||||||

| Table heating | Steam heating(Fixed,80-100ºC) | ||||||

| Electric heaing(Option,30-110ºC adjustable) | |||||||

| Buck heating | Option | ||||||

| Upward chinmey | Option | ||||||

| Iron hanger | Option | ||||||

| Table size | 1500*780mm 1200*780mm Customized is available | ||||||

| Feature |

| 1. Integrated design, inbuilt with steam generator automatically control adding water and heating.Quickly heating and sufficient pressure. |

| 2. Inbuilt with steam furnace, short steam pipe and low heating loss, to keep steam temperature and dry. |

| It solves the shortcomings of using traditional large boilers, long steam supply pipelines, high heating loss and wet steam. |

| 3. Energy-saving type advantages: |

| Unique steam exhaust recycling structure ,fully use steam exhaust, which saves about 40% steam consumption compared with other type. |

| Solve the shortcomings of traditional steam exhaust directly returning to the water tank: |

| 1. Makes the water pump heating and shorten its life . |

| 2. The water vapor generated by the boiling water in the water tank will not only affect the working environment, but also make the clothes |

| easily to getting moist and mold. |

| 4. Table with iron end-steam heating,save energy saving. |

| 5. Use stainless steel furnace, steam without stains, to avoid making the clothes dirty. |

| 6. Use Stainless steel water tank, |

| 7. Without changing the heating pipe power, the external volume of the heating pipe is increased, the heat receiving area of the water inside the |

| furnace is increased, so that the heating and heating temperature will be speed up, the steam volume is sufficient. |

| 8. Use heatproof water pump,it is not easy to get rusty and stuck. |

| 9. Warning function of water shortage ,avoiding the heating pipe damaged because of heating without water |

| 10. Equipped with moving casters for conveniently moving. |

Remark:

Offer 12 months quality warranty.

Shipping terms: EXW/FOB/ CFR/CIF Shenzhen or Guangzhou

Payment term: Support T/T , 30% as deposit and balance should be paid before shipment.

Shipping term:About 7-15 days after receipt the deposit,but it also according to the quantity.

Related Search

Steam Boiler

Steam Vacuum

Fired Steam Boiler

Electrical Steam Boiler

Steam Generator Boiler

Steam Vacuum Cleaners

More>>

.jpg)